Hamburger Tuckerboot

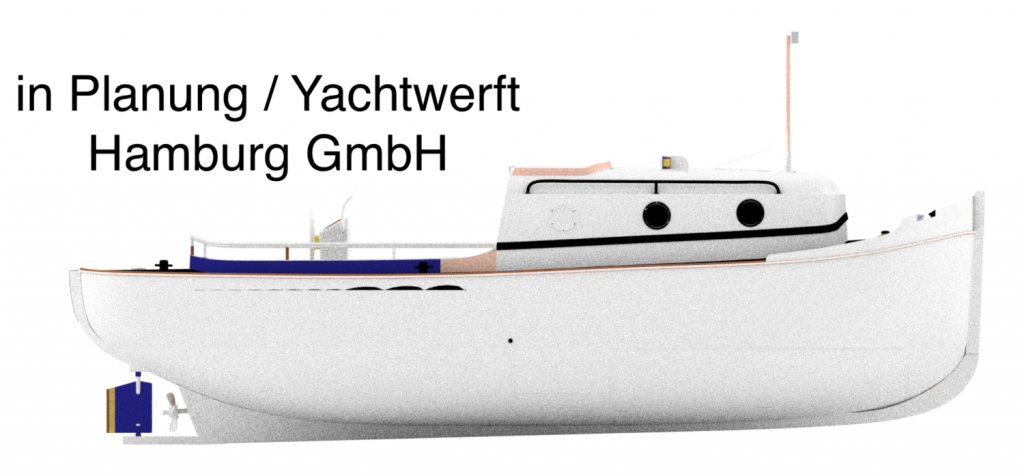

For the 700th anniversary of Hamburg-Blankenese, the designer Reinhard Stelzer presented the Hamburg Tuckerboot for the first time in traditional wooden construction, from which he then developed the Hamburg Tuckerboot 675 in a modern plastic construction.

Whether in the starting version as an open boat with tiller steering or as a cabin version with full equipment including a wooden deck, stove, on-board toilet and wheel steering, this boat offers all options for customizing it according to customer requirements.

Since the Hamburg Tuckerboot is purely a displacer with an electric drive, the noise emissions are far lower than those of a boat with a combustion engine.

The manufacture, maintenance and repair of yachts is one of our main activities as a boat builder. Boats and yachts have been mainly made of GRP since the 1960s. Today, in addition to emissions in the manufacturing process, there is also the problematic disposal of fiber composite materials. These materials consume a lot of CO2 during production and can only be treated as hazardous waste after their life time.

Cold-curing plastics (GRP) and adhesives based on polyester and epoxy resin are mainly used in yacht construction. Products (boats) are made from composite materials of a wide variety of plastics.

The aim of the project is to produce a boat that:

A: contains the maximum proportion of renewable raw materials

B: is subject to the lowest possible consumption of CO2 during the construction phase

C: emits as little CO2 as possible during operation

In addition to the maximised use of renewable raw materials, recycled materials are used. For example, lightweight panels made from recycled PET foam (beverage bottles) will be used as the core material. All materials are produced regionally as far as possible. The technical equipment as well as the drive and deck fittings are supplied with a maximum proportion of producers from Germany and Europe.

This also applies to consumables and to ensure the energy required for production from renewable sources. Existing negative molds are reprocessed to produce the hulls and decks so that they can continue to be used in the future.

To keep CO2 emissions as low as possible during the life of the boat, the prototype is designed and equipped with an electric drive train. This will also eliminate the risk of fuel spillages and reduce noise pollution.

The goal of making a boat with a modern composite construction from renewable raw materials is an innovation. It must be checked in each area which fiber is the right one. The processes are then implemented in production and provided with new standards.